I have a color laser printer that I purchased 16 years ago. (Scary.)

It is a Konica-Minolta Magicolor 2450. Its print quality is quite nice. But it is horribly noisy, and its mechanical reliability has never been great. It was only a few months old when it first failed, simply because an internal part got unlatched. (I was able to fix it and thus avoid the difficulties associated with having to ship something back that weighs at least what, 20 kilos or more?)

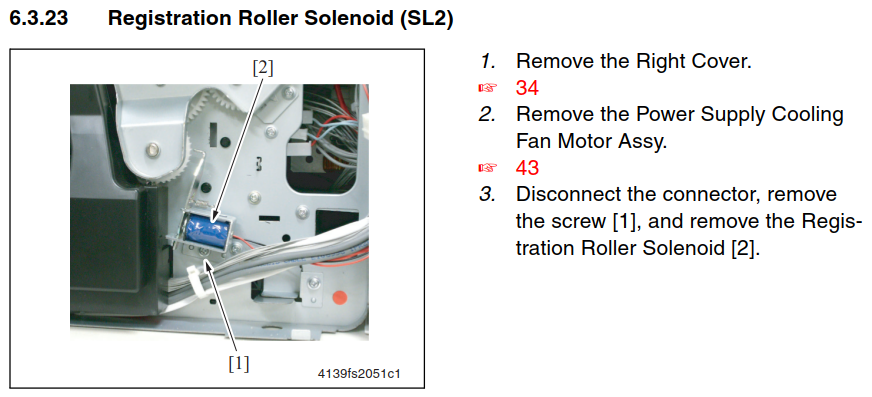

Since then, it has had a variety of mechanical issues but, as it turned out, essentially all of them related to solenoids that actuate mechanical parts.

When I first diagnosed this problem (yes, having a service manual certainly helped), what I noticed was that the actuated part landed on another metal part that had a soft plastic pad attached. I checked online but the purpose of these plastic pads was unclear. Perhaps to reduce noise? Well, it’s a noisy beast anyway, a few more clickety-click sounds do not make a difference. The problem was that these plastic pads liquefied over time, becoming sticky, and that caused a delay in the solenoid actuation, leading to the problems I encountered.

Or so I thought. More recently, the printer crapped out again and I figured I’d try my luck with the screwdriver one more time before I banish the poor thing to the landfill. This time around, I completely removed one of the suspect solenoids and tested it on my workbench. And that’s when it dawned on me.

The sticky pad was not there to reduce noise. It was there to eliminate contact, to provide a gap between two ferrous metal parts, which, when the solenoid is energized, themselves became magnetic and would stick together. In other words, these pads were essential to the printer’s operation.

Inelegant, I know, but I just used some sticky tape to fashion new pads. I reassembled the printer and presto: it was working like new!

Except for its duplexer. But that, too, had a solenoid in it, I remembered. So just moments ago I took the duplexer apart and performed the same surgery. I appear to have been successful: the printer now prints on both sides of a sheet without trouble.

I don’t know how long my repairs will last, but I am glad this thing has some useful life left instead of contributing to the growing piles of hazardous waste that poison our planet.