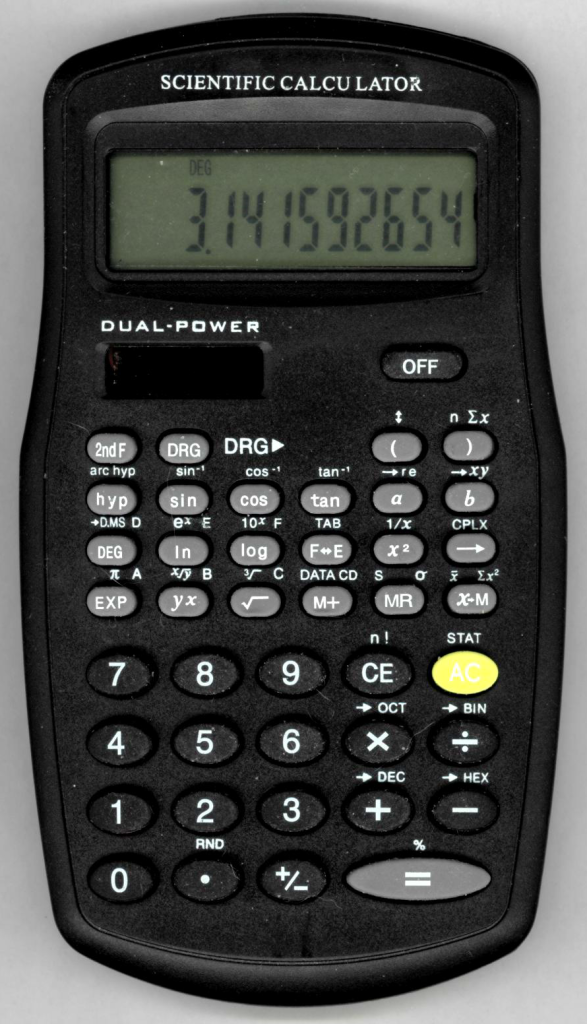

Though vintage programmable calculators remain one of my oddball hobbies, it’s been a while since I last mentioned them in this blog. And it’s especially rare that I’d write about a non-programmable, perfectly ordinary, dirt cheap, dollar-store quality mass-produced Chinese scientific (“56-function”, standard chip) calculator, but this one is different.

Why? Because I fixed the darn thing, that’s why.

Why am I so proud of my accomplishment, fixing something that most folks would have thrown away as a worthless, broken piece of junk? There is a very specific reason.

The bane of cheap calculators for the past 20-odd years has been the connection between the calculator’s main circuit board and its liquid crystal display. The liquid crystal display contains transparent connections, but these, rather obviously (it’s glass!) cannot be soldered. So how do you connect the display and the circuit that drives the display? In the earliest LCD devices, this was accomplished by a strange, rubbery part, a conductive silicone “zebra strip” that made an electrical connection between a series of connectors on the circuit board and the corresponding leads on the display glass. The device worked if this zebra strip was properly sandwiched between the display and the circuit board and held together tightly, which required an appropriate mechanical construction.

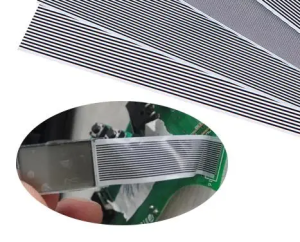

More recently, these have been replaced by, ahem, I think they’re usually referred to as “zebra stripes” or maybe “zebra lines”: essentially, paper-thin sheets of plastic with parallel conducting lines. A short strip, or stripe, attaches on one end to connections on the circuit board, and on the other end, to the LCD display. The attachment is adhesive (which may be heat activated) and once attached, there’s no need for mechanical pressure to hold the parts together. This, I presume, makes the design less constrained, and reduces manufacturing costs.

The problem is that these zebra stripes can become detached. This leads to a failing display: Digits vanish, segments vanish, crosstalk appears, the display becomes garbled and unreadable.

In some cases, this can be reversed by (very) carefully pressing down the stripe on both ends, with a hard but not too sharp tool as you wish to apply pressure to reattach the adhesive, not destroy the plastic. Sometimes, a heated tool works better. But the result is uncertain: Sometimes it works, sometimes it doesn’t, sometimes it fails a few hours, days, weeks later.

If the zebra stripe is mostly or completely detached, or if it is damaged, the device is dead. Or so I thought… until now.

When this nameless “scientific calculator” came into my possession (found in a small bag of goodies that we bought at a thrift store) it indeed seemed hopeless. But I decided that it can serve as a perfect test case. For the first time ever, I endeavored to purchase a small piece of replacement zebra stripes of the right size from AliExpress. I had no idea how to use it properly, or indeed if it would work or not, but I figured it’s worth trying.

My first few attempts were disastrous. Applying too much heat destroyed the zebra stripe. Glue and molten plastic residue contaminated both the circuit board and the LCD display. Scraping it off was difficult and I was probably one bad move away from cracking the display.

But I didn’t. And on the fourth try, the display more or less came to life! I was ready celebrate success even though the display was not quite flawless, as it was already a far better result than I had hopes for. But at this point I noticed that although the display was now working, the calculator itself wasn’t: it no longer responded to any of its keys. I went through several iterations trying to troubleshoot this new problem before I noticed something: The zebra stripe I used was a tad longer than it should have been, and it made contact with another lead on the calculator’s circuit board, effectively short-circuiting its keyboard.

Once I corrected that, the calculator not only came back to life, even its display was now working like a charm. I feel like celebrating.

I don’t know how long it sill last: Cheap hardware is still cheap hardware. But now I know that repairing broken zebra stripes is possible.

So yes, this is how I am having fun during the long Easter weekend. Happy Bunny Day!